Office: (314) 241-5333

Sales Hours

Mon - Fri: 08:00AM - 05:00PM

Saturday: Closed

Sunday: Closed

Adress

5737 W Park Ave

St. Louis, MO 63110

English

Abrasive Recycling

How many tons of reusable abrasive do you throw away on each project?

Higher performing abrasives allows owners to utilize recycling methods.

New – We now carry Clemco Blasting Equipment

With modest levels of investment, a blast shop can recycle suitable abrasive media 1 to 5 times.

A larger up front investment will allow a continuous recycling operation. This gives the advantage of THE lowest cost per square foot for any given high performance blast abrasive.

We have broken down recycling solutions into three levels:

Level 1 Basic Recycling – Approximately $1000 to $5000 investment:

- Offers 1 to 3 reuses of the spent abrasive

- Requires manual spent abrasive pickup (no automation) and conveyance to the hopper or blast pot

- Includes screening to remove only large debris

- No screening for fines

- Will need to check profile height of recycled abrasive blast for approval

- Estimated to save 1 ton of high performance abrasive for every 3 to 5 tons purchased

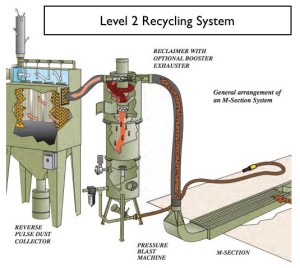

Level 2 Intermediate Recycling – Approximately $10K to $25K investment:

- Offers 2 to 5 reuses of the spent abrasive

- Requires Sweep-In system or Bobcat spent abrasive pickup

- Includes pneumatic or mechanical conveyance of spent abrasive to hopper or blast pot

- Large debris is removed

- Fines are removed

- Number of reuses are dependent on specific abrasive media and blast impact force

- Recycled abrasive can be mixed with virgin abrasive

- Profile height of working mix abrasive needs approval

- Estimated to save 1 ton of high performance abrasive for every 2 to 4 tons purchased

Level 3 Closed Loop Recycling – Approximately $25K or more investment:

- Turns will be dependent upon specific abrasives selected for job

- Automated spent abrasive pickup system

- Includes pneumatic or mechanical conveyance of spent abrasive to hopper or blast pot

- Large debris is removed

- Fines are removed

- Number of reuses are dependent on specific abrasive media and blast impact force

- Recycled abrasive can be mixed with virgin abrasive

- Profile height of working mix abrasive needs approval

- Estimated to save 1 ton of high performance abrasive for every 1 to 3 tons purchased