For Blast and Paint shops, the very heart of the operation is the Compressor. While the Compressor may be the most expensive component, sufficient high quality compressed air is the most essential element for successful Blast & Paint shop operations.

A Compressor’s function is to supply a large amount of air to the Blast & Paint equipment in a short period of time – Blast shops singularly consume inordinate amounts of compressed air.

What is not quite as obvious is that while compressing air we are also compressing all the latent moisture in that airspace – in effect creating a highly concentrated moisture laden mixture.

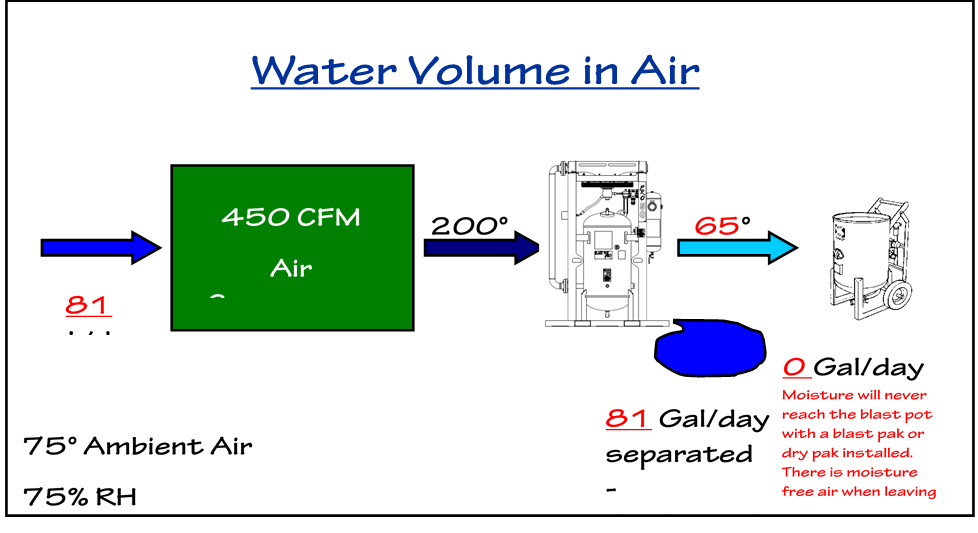

For example, at 75% RH and 75`F temperature, a standard 450 CFM Compressor (450 Cubic Feet per Minute compression), we are inadvertently concentrating & creating 81 gallons of water per 8-hour day! In other words, in addition to the compressed air and abrasive, we are sending 10 gallons of water through the Blast system every hour! Refer to diagram below:

That much water per day running through our Blast equipment will greatly affect performance:

- Increased Media Cost: When the Blast Media is wet (for dry blasting systems), surging at the nozzle will occur. Blaster will respond by opening abrasive metering valve and more abrasive is blown through the system – wasting abrasive.

- Reduced Productivity: Wet air and abrasive is slugged through the system instead of discreet, dry particles – substantially slowing the blast cleaning speed.

- Decreased Operating Efficiency: Rapid flash rusting of blasted steel occurs as a result of using wet air/abrasive – causing loss of required degree of cleanliness.

- Increased Downtime: Blockages and lack of efficient flow – more work stoppages – more frustration for the Blaster.

- Increased Equipment Cost: Wet air and abrasive will exacerbate wear and tear – and erosion – on the Blast Equipment wear components.

In order to combat excessive moisture/water in the compressed air stream, successful Blast & Paint shops utilize one, or more, of the available moisture removal methods.

Air Dryers come in various shapes, sizes and functionality. For example, the Aftercooler, Water Separator, Filter Housing and finally the Deliquescent Dryers (e.g., Van Air’s DryPak Pro & BlastPak). Some simply separate the free liquids from the hot, compressed, moisture laden air stream using “filters” – such as separators or air filters – While others like the Air -Cooled Aftercoolers are used to reduce the temperature of the compressed air. These are not technically “dryers” – but by function by reducing the temperature of the compressed air which precipitates the moisture which condenses out of the air stream. Deliquescent Desiccant dryers will withdraw moisture from the air stream. Even large expansion (surge) tanks are inexpensive ways to cool and capture some of the condensate.

More efficient Air Dryers extract a higher percentage of the moisture out of the compressed air stream include:

- Coolpaks

- Aftercoolers

- Deliquescent Dryers

- Combination systems

Examples include: